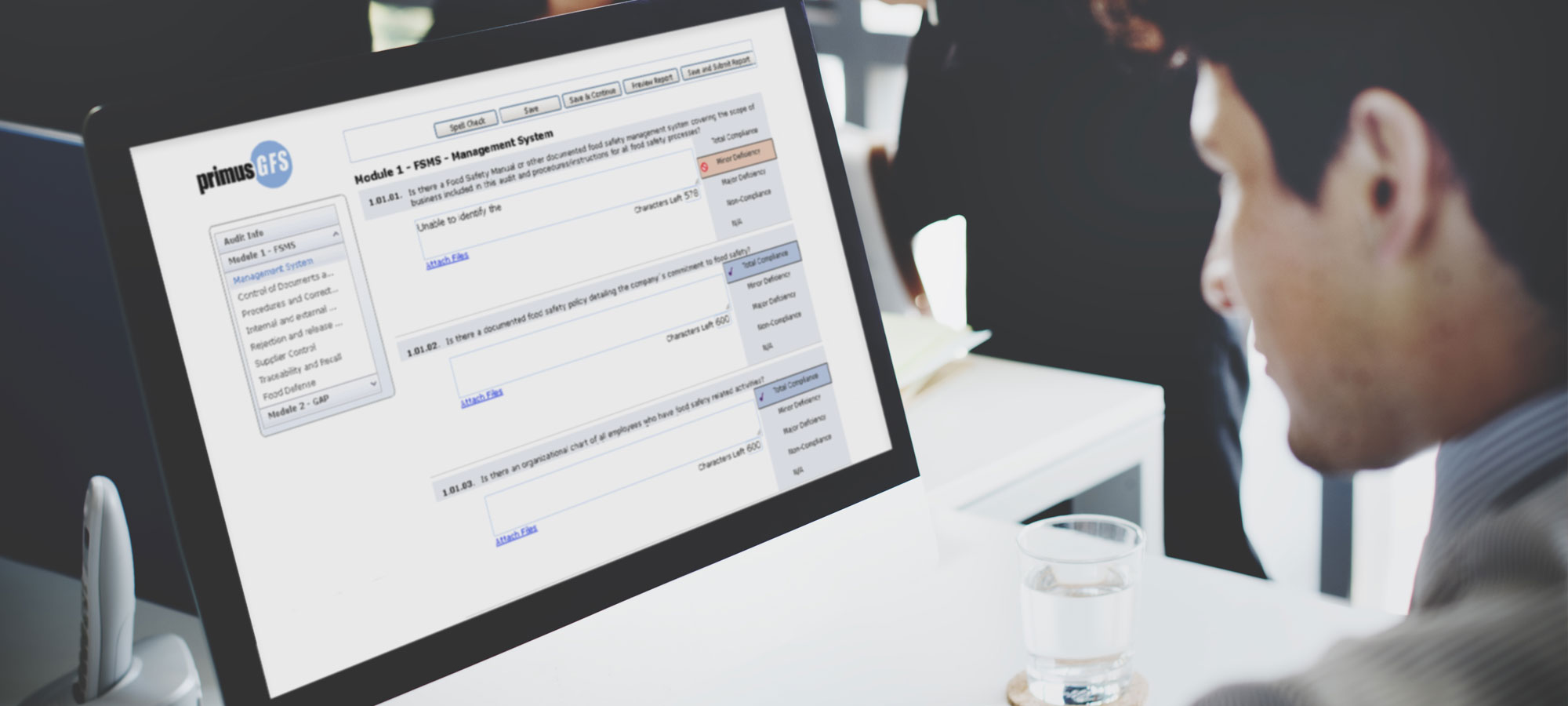

What Is the PrimusGFS Audit Certification Program?

PrimusGFS is a Global Food Safety Initiative (GFSI) recognized audit Certification Program, with certification in 22 countries. Endorsed by more than 7,326 organizations, PrimusGFS provides total produce supply chain coverage.

Which Modules are right for my Operation?

Farm

Also known as Ranch. This type of audit is applicable to farming and growing of plants, grains, and pulses for food industry on open land conditions.

Module 1

Applicable for all production areas and is the assessment of an operation’s Food Safety Management System (FSMS). The FSMS is a set of interrelated systems that when used in combination ensure that food is safe for human consumption. It incorporates, GAPs, GMPs/PRPs, GHPs, HACCP and other practices such as regulatory requirements and communication to ensure food safety is maintained.

Module 2 – FARM

Assessment of an Operation´s Good Agricultural Practices (GAPs) for farm activities related to irrigation and water use, soil amendments, land use (previous and adjacent), animal access (domestic/wild), equipment, worker health & hygiene practices, pesticide usage.

Indoor Agriculture

Also known as Greenhouse. This audit is applicable to Farming and Growing of plants for food industry in a controlled environment in temporary or permanent enclosed structure (e.g., greenhouse, vertical growing, hydroponics, mushroom farms, etc.).

This does not include shade or hoop houses.

Module 1

Applicable for all production areas and is the assessment of an operation’s Food Safety Management System (FSMS). The FSMS is a set of interrelated systems that when used in combination ensure that food is safe for human consumption. It incorporates, GAPs, GMPs/PRPs, GHPs, HACCP and other practices such as regulatory requirements and communication to ensure food safety is maintained.

Module 3 – Indoor Agriculture

Assessment of Good Agricultural Practices (GAPs) for indoor growing activities related to irrigation and water use, soil amendments, animal access (domestic/wild), equipment, tools and buildings, worker health & hygiene practices, pesticide usage.

Harvest Crew

Applicable to harvesting on Farm or Indoor Agriculture. Harvesting (gathering) a crop from the production site (e.g., pulling or digging produce from the ground, picking it, separating it from the plant), either manually or mechanically.

Module 1

Applicable for all production areas and is the assessment of an operation’s Food Safety Management System (FSMS). The FSMS is a set of interrelated systems that when used in combination ensure that food is safe for human consumption. It incorporates, GAPs, GMPs/PRPs, GHPs, HACCP and other practices such as regulatory requirements and communication to ensure food safety is maintained.

Module 4 – Harvest Crew

Assessment of Good Agricultural Practices (GAPs) for harvesting activities related to equipment, tools, worker health & hygiene practices, harvest practices, transportation and on-site storage.

Packinghouse

Applicable to Facilities where commodities are sorted and/or sized, may be minimally trimmed (not altered in form), washed or not washed, may have post-harvest fungicide treatments applied (e.g., wax, sprout inhibitor) and packed for commercial distribution and use by consumer or retail establishment.

Module 1

Applicable for all production areas and is the assessment of an operation’s Food Safety Management System (FSMS). The FSMS is a set of interrelated systems that when used in combination ensure that food is safe for human consumption. It incorporates, GAPs, GMPs/PRPs, GHPs, HACCP and other practices such as regulatory requirements and communication to ensure food safety is maintained.

Module 5 – GMP

Assessment of Good Manufacturing Practices for a Facility operation to mitigate potential and real risks. Key categories include, facility design and construction material, water supply, plumbing and toilet facilities, equipment and utensils, raw food handling and process controls, personal hygiene, pest control, and waste disposal.

Module 6 – HACCP

Assessment of Hazard Analysis and Critical Control Point principles used to identify, prevent, and control food safety hazards.

Module 7 – Preventive Controls *optional

Assessment of the operation’s FSMA Preventive Controls for Human or Animal Food Plan. Preventive controls minimize or prevent food safety hazards. These controls include, process, allergen, sanitation and other additional controls.

Cooling & Cold Storage

This type of audit is adequate for facilities that not only receive, and store finished goods but perform pre-cooling techniques and/or cooling activities.

Module 1

Applicable for all production areas and is the assessment of an operation’s Food Safety Management System (FSMS). The FSMS is a set of interrelated systems that when used in combination ensure that food is safe for human consumption. It incorporates, GAPs, GMPs/PRPs, GHPs, HACCP and other practices such as regulatory requirements and communication to ensure food safety is maintained.

Module 5 – GMP

Assessment of Good Manufacturing Practices for a Facility operation to mitigate potential and real risks. Key categories include, facility design and construction material, water supply, plumbing and toilet facilities, equipment and utensils, raw food handling and process controls, personal hygiene, pest control, and waste disposal.

Module 6 – HACCP

Assesment of Hazard Analysis and Critical Control Point principles used to identify, prevent, and control food safety hazards.

Module 7 – Preventive Controls *optional

Assessment of the operation’s FSMA Preventive Controls for Human or Animal Food Plan. Preventive controls minimize or prevent food safety hazards. These controls include, process, allergen, sanitation and other additional controls.

Processing

This audit is suited for production facilities producing perishable food from plant products or ambient stable products. Examples of facilities include controlled temperature environment where whole commodities are minimally processed and altered in form by peeling, slicing, chopping, shredding, coring, or trimming, with or without washing, prior to being packaged for use by the consumer or a retail establishment or baking, bottling, canning, cooking, etc. (e.g., canned goods, pre-cut, packaged, ready-to-eat salad mixes).

Module 1

Applicable for all production areas and is the assessment of an operation’s Food Safety Management System (FSMS). The FSMS is a set of interrelated systems that when used in combination ensure that food is safe for human consumption. It incorporates, GAPs, GMPs/PRPs, GHPs, HACCP and other practices such as regulatory requirements and communication to ensure food safety is maintained.

Module 5 – GMP

Assessment of Good Manufacturing Practices for a Facility operation to mitigate potential and real risks. Key categories include, facility design and construction material, water supply, plumbing and toilet facilities, equipment and utensils, raw food handling and process controls, personal hygiene, pest control, and waste disposal.

Module 6 – HACCP

Assessment of Hazard Analysis and Critical Control Point principles used to identify, prevent, and control food safety hazards.

Module 7 – Preventive Controls *optional

Assessment of the operation’s FSMA Preventive Controls for Human or Animal Food Plan. Preventive controls minimize or prevent food safety hazards. These controls include, process, allergen, sanitation and other additional controls.

Storage & Distribution

This audit is meant for Storage, distribution, and/or logistics operations for the storage and transport of perishable or non-perishable food, feed, or packaging.

Note: any packing with labelling activities is excluded.

Module 1

Applicable for all production areas and is the assessment of an operation’s Food Safety Management System (FSMS). The FSMS is a set of interrelated systems that when used in combination ensure that food is safe for human consumption. It incorporates, GAPs, GMPs/PRPs, GHPs, HACCP and other practices such as regulatory requirements and communication to ensure food safety is maintained.

Module 5 – GMP

Assessment of Good Manufacturing Practices for a Facility operation to mitigate potential and real risks. Key categories include, facility design and construction material, water supply, plumbing and toilet facilities, equipment and utensils, raw food handling and process controls, personal hygiene, pest control, and waste disposal.

Module 6 – HACCP

Assessment of Hazard Analysis and Critical Control Point principles used to identify, prevent, and control food safety hazards.

News

Top Performing Certification Program, Powered by Azzule

Azzule’s Certification Program Software allows Certification Program Managers unprecedented insight into their Certification Programs’ performance and complete control of certifying bodies and reporting via data and expert-driven Integrity Programs and analytics. Powered by Azzule, our partnering Certification Program are integrated directly into your Supply Chain Program for easy access for managing and meeting regulatory and customer compliance requirements.